Case Study

Share this

article

The Design and Analysis of "Quantum Cloud"

-

Steel sculpture

by internationally recognised sculptor Antony Gormley

-

Custom fractal

growth software written to develop the structural form

-

Linear,

nonlinear and wind assessment analysis

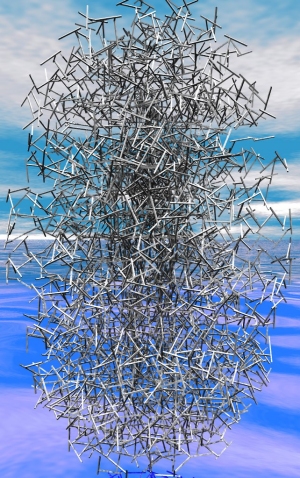

"Quantum Cloud" is a 30 metre high x 16

metre wide x 10 metre deep elliptical cloud sculpture which stands on four cast iron

caissons in the River Thames adjacent to the O2 arena and the

Emirates Air Line cable car in London, UK. It is

the work of "Angel of the North" sculptor, Antony Gormley,

and is formed

from 1.5 metre long lengths of randomly oriented steel sections which diffuse at the edges

and condense into a 20 metre high human body form at the centre. At

the time of its construction, in 1999, it was the

tallest sculpture in the UK. The engineering design team of Elliott Wood Partnership and

LUSAS consultancy services worked closely with the Gormley to develop the full scale realisation of his vision for

the client, the New Millennium Experience Company. Fractal growth software written by

LUSAS was used to develop the structural form, and modelling and

analysis with LUSAS finite element analysis ensured the unique

structure was fit for purpose.

Overview of the structure

The sculpture,

whilst visually random in nature, in fact consists of three distinct regions. A central

structural core of 1.65m sided, tetrahedral steel units provides support for an outer

steel tendril region that forms the cloud shape, and also provides the restraint for an

inner body form structure. The structural core rests on a lattice of 533x210x92 Universal

Beams via stools at every tetrahedral and lattice intersection. The steel lattice beams

are, in turn, bolted to 1016x305x272 Universal Beams that span between the four existing

caissons.

Each of

the 325 tetrahedral units is formed from four, 1.5m long, steel hollow sections welded

together. Every unit is connected to its neighbours by a unique casting to which it is

initially connected via steel pins that are subsequently removed after the joints are

welded. Each tendril is fabricated in one piece for bolting to a spigot on the

main core. The body form members are threaded through the core and also held in place by

spigots. Galvanised, steel, 70x70x5 Square Hollow Sections are used throughout the core

and for the first member of the tendril that is welded to it. 70x70x3.6 Square Hollow

Sections are used elsewhere. Grade 50 steel with a yield strength of 420Mpa was used

throughout the structure with the exception of certain members at the base of the core

where steel with a certified 25% greater yield strength is used. In all, approximately

5.5km of steel section is used, weighing nearly 50 tonnes in total.

| Generation of the structural forms

|

Laser scans of the sculptor's body provided the raw data to define a 3D boundary

or 'domain' of the body form. The structural

core of the sculpture required as large a footprint as possible to help resist prevailing

wind forces. This, in conjunction with the estimated number of castings that could be

fabricated within the time available ultimately dictated the size of the structural core

into which the body was fitted. Laser scans of the sculptor's body provided the raw data to define a 3D boundary

or 'domain' of the body form. The structural

core of the sculpture required as large a footprint as possible to help resist prevailing

wind forces. This, in conjunction with the estimated number of castings that could be

fabricated within the time available ultimately dictated the size of the structural core

into which the body was fitted.To generate the

arrangement of members in the central structural core, FEA wrote custom software that,

from an initial starting point at the level of the supporting steel lattice, generated a

randomly oriented layer of tetrahedral units to occupy the width of the domain for a

particular level of the structure. Once one layer was complete, the software then used the

previously created nodal data to build the next layer, and so on, until the supporting

structural core of 17 layers was complete. An additional layer of tetrahedral units was

also generated beneath the supporting steel lattice to provide fixity for the tendrils in

this region. |

Chaos theory and fractal growth

techniques were used to create the outer tendrils representing the cloud structure. Chaos theory and fractal growth

techniques were used to create the outer tendrils representing the cloud structure.- Using the same specially written software that generated the core, and

working from the stored nodal data for the edges of the core, tendrils were 'grown' from

the outermost tetrahedral units in a series of up to 5 organic growths or 'expansions'.

- A database of member locations was stored by the fractal software and

used to enable clash detection of new members with previously generated ones.

Similar fractal techniques generated the arrangement of the body

form members using the specified body domain to limit the area of growth. Similar fractal techniques generated the arrangement of the body

form members using the specified body domain to limit the area of growth.- The first complete set of tendril and body member generations gave an

indication of how much steel would be required to create the sculptor's desired visual

appearance and also provided an initial estimate of the total weight of the structure.

- The fractal software also generated LUSAS modelling and analysis data

files, a DXF file for use in creating detailed member design drawings and an input file

for SolidWorks which was used to create 3D casting models for subsequent rapid

prototyping.

As Geoff Paice, Deputy Head of Engineering Services at

LUSAS explains:

"Our custom software converted the digital design directly into fabrication schedules

and erection drawings, thereby minimising the traditional paper-copy approach and

virtually eliminating manual drafting requirements. This potentially saved the project

months of CAD time and allowed the design to evolve while the fabrication proceeded."

|

Preliminary analysis and testing Preliminary analysis and testing

A preliminary LUSAS analysis of the core at an early stage of its

development was carried out to find its Ultimate Limit State and to see if the proposed

method of design and analysis needed to be re-assessed. In modelling the structure, 2

engineering beam elements were used for each tetrahedral member and the castings were

modelled using a separate beam element for each leg joint. A single tetrahedral unit was

built and load tested to failure by the fabricators, Tubeworkers (Structures) Ltd. This

unit was also modelled, loaded and analysed in LUSAS. The results correlated extremely

well, showing the same failure mechanism, and verified the proposed modelling approach.

Prior to the full development of the structure, a trial assembly of 10 tetrahedra in a

pyramid of 3 layers was performed to prove both the construction sequence and the accuracy

of the fabricated components. This confirmed that the designer's methodology was suitable.

Structural development and the exchange of project data

In a series of iterative processes the final form gradually began to evolve. The

LUSAS web site was used as a live communication tool by the project partners to exchange data and view proposed

designs. Ray traced images and VRML models of potential structural forms, created by using

the LUSAS Programmable Interface (LPI), were put onto the web site to allow the sculptor

to examine the structure from every conceivable angle, and to make suggestions for

improvements. This totally eliminated the 'paper copy' approach and helped to speed-up the

development process enormously.

Structural analysis

For each re-development of the tendril region, wind assessment with a 25

year return period was carried out to BS6399 : Part 2 : 1995, The Code of Practice for

Wind Loading, to see how dense the cloud could be built. The wind loading assessments

provided a set of equivalent loads which were applied to the core members in the LUSAS

model for each of the eigenvalue and nonlinear analyses of the structure. Applying

equivalent loads in this way reduced the model size and helped to speed-up the solution

times.

At every project landmark, eigenvalue analyses of the whole structure

were carried out to assess likely wind induced oscillations. In addition, a detailed

analysis of one of the longest tendrils was done using full wind loading acting as a

dynamic pressure to evaluate the bending moments at the bolted connections. Once all

aspects of the structure had been approved a final, more rigorous, elasto-plastic analysis

was performed with the certified higher strength steel members in those regions where the

earlier analyses had indicated high stress concentrations. At every project landmark, eigenvalue analyses of the whole structure

were carried out to assess likely wind induced oscillations. In addition, a detailed

analysis of one of the longest tendrils was done using full wind loading acting as a

dynamic pressure to evaluate the bending moments at the bolted connections. Once all

aspects of the structure had been approved a final, more rigorous, elasto-plastic analysis

was performed with the certified higher strength steel members in those regions where the

earlier analyses had indicated high stress concentrations.

In carrying out the wind assessment, two

shielding calculations were performed. The empirical method of Eden, Butler and Patient

was used initially to calculate the "total" solidity of the frame. This method

sums the projected areas of all members and divides by the total envelope area. A more

rigorous shielding analysis method for multiple plane frames was also used as described in

"The Designers Guide to Wind Loading of Building Structures, Part 2: Static

Structures". This method divides the space envelope of the sculpture into 1m3

zones. The layers normal to the wind were considered as "plane frames"

positioned at the centre of the layer, and the system was analysed as a series of 17

frames. Each 1m2 of cell on elevation was treated separately so that the

variation of solidity on elevation could be captured. The shielding effect of upstream

frames was computed using a summation method, leading to a build-up of shielding on the

downwind frames. In fact, the members at the back of the densified zone are almost totally

shielded. In both cases, a complete model of the sculpture was used for calculations, in

which, structural core, body form, and tendril expansion zones were included. It provided

a reasonable basis for the assessment of solidity through the structure for the most

onerous condition of a face-on wind.

Results

Using the comprehensive results processing facilities in

LUSAS, maximum and minimum envelopes of factored dead and wind loading were defined and

the results were selected for viewing. The Groups facility was of particular use in this

analysis where the structure is so complex and plotted values cannot be easily seen. The

use of Groups allowed the results for a particular layer or region of the structure to be

looked at in isolation, as for example, for each layer of the structural core where a

force/moment diagram was plotted to show stresses and bending moments in each of the

tetrahedral members. Using the comprehensive results processing facilities in

LUSAS, maximum and minimum envelopes of factored dead and wind loading were defined and

the results were selected for viewing. The Groups facility was of particular use in this

analysis where the structure is so complex and plotted values cannot be easily seen. The

use of Groups allowed the results for a particular layer or region of the structure to be

looked at in isolation, as for example, for each layer of the structural core where a

force/moment diagram was plotted to show stresses and bending moments in each of the

tetrahedral members.

Conclusions

The use of innovative engineering ideas from all members of the project

team, LUSAS Engineering Consultancy Services' skill in producing complex custom software to grow and develop potential

structural forms, and the use of LUSAS Civil and Structural analysis software to

model and prove the structural integrity of the sculpture, ensured that the design and

analysis of a complex structure was completed to the sculptor's satisfaction in a very

tight timescale.

Project Partners Project Partners

The following companies worked in partnership with the sculptor,

Antony Gormley, to develop the

full scale realisation of his vision, which stands adjacent to the Millennium Dome

(now the O2 Arena) in Greenwich, UK.

Engineering Design Team: LUSAS and Elliott Wood Partnership

Contractor: Tubeworkers (Structures) Ltd

Production of patterns for

investment casting, using rapid prototyping techniques: Innovative Manufacturing Centre

Investment Casting production:

MBC Precision Castings

|

"Quantum Cloud

is a project that can only be realised with digital design systems and I am very fortunate

to have collaborated with energetic and ground-breaking engineers.

The result, a

combination of art and technology, will be a monument to the future, expressing the

potential of the human being at the end of the twentieth

century."

Antony

Gormley

Share this

article

Find out more

Other LUSAS Civil &

Structural case studies:

|

|

Software Information

|